Nanorobot Communication Techniques:

This work presents chemical communication

techniques for nanorobots foraging in fluid environments

relevant for medical applications. Unlike larger robots, viscous

forces and rapid diffusion dominate their behaviors.

Examples

range from modified microorganisms to nanorobots using

ongoing developments in molecular computation, sensors and

motors.

I. INTRODUCTION

Nanorobots with sizes comparable to bacteria could provide

many novel capabilities through their ability to sense and

act in microscopic environments. Particularly interesting are

biomedical engineering applications [1], [2], where nanorobots

and nanoscale-structured materials inside the body provide

significant improvements in diagnosis and treatment of disease

[3], [4], [5]. The rapid progress in building nanoscale devices

should enable a wide range of capabilities [6]. For example,

ongoing development [7], [8], [9], of molecular-scale

electronics, sensors and motors provides components to enable

nanorobots [10]. Demonstrations of programmable bacteria

[11] can produce computation capability for nanodevices. The

ways to enable Nano-Build Hardware Integrated Systems has

been demonstrated and manufacturing techniques are

advancing gradually [9]. The development of nanosystems for

control of nanorobots to perform specific tasks in medicine

may also enable improvements for nanotechnology automation

[12], [13]. The next level of challenge for nanotechnology

development may address intelligent control system with

device manufacturing and automation in a broad sense [14],

[15].

We present a comprehensive work on techniques for

nanorobots communication based on extensive numerical

results and real time 3D simulation. The approach in this paper

is applied to the following biomedical problem: the nanorobots

with embedded chemical sensors perform the detection of a

single tumor cell in a small venule [16], [17], [18]. The venule

is one among many types of vessels from the human body.

Integrated nanosensors can be utilized for such a task in order

to find intensity of E-cadherin signals [19], [20]. Brownian

motion has a direct influence in a microfluid workspace,

which for active communication makes stigmergy the natural

way for near distance interaction [21]. Thus, communication

and nanorobot control reacting to changes in the environment

is quite appropriate for our study as described in this paper.

II. BEHAVIOR IN FLUID MICROENVIRONMENTS

We consider nanorobots operating in small blood vessels. The

fluid in the vessels contains numerous cells, several microns in

diameter. Viscosity dominates the nanorobots motion through

the fluid in the environment, with physical behaviors quite

different from our experience with larger organisms and robots

[22], [23]. The ratio of inertial to viscous forces for an object

of size R moving with velocity v through a fluid with viscosity

η and density ρ is given by the Reynolds number as follows: Vein internal view without the red cells. The tumor cell is the target

represented by the pink sphere located left at the wall. All the nanorobots

swim near the wall to detect cancer signals.

Typical values for density and viscosity in blood plasma are

represented by equations 2 and 3 respectively.

3 ρ = 1g / cm (2)

10 g / cm.s −2 η = (3)

Flow speeds in small blood vessels are about 1mm/s. This is

also a reasonable speed for nanorobot motion with respect to

the fluid [3],providing

3 Re 10 − ≈ for a 1-micron nanorobot,

and thus viscous forces dominate. Consequently, nanorobots

applying a locomotive force quickly reach a desired velocity

in the fluid. Hence, applied force is proportional to velocity

rather than the direct correlation applied in the acceleration of

Newton’s law F = ma . Diffusion arising from thermal

motion of molecules (Brownian motion) is also important.

Depending on the object’s size, the diffusion coefficient D

characterizes the resulting random motion. In a time t, the

root-mean-square displacement due to diffusion may be

defined as:

k = 6Dt . (4)

For a nanorobot ≈1µm operating at body temperature, this

displacement is ≈ t microns with t measured in seconds.

Brownian motion also randomly changes the nanorobot

orientation. Chemicals have much larger diffusion coefficients

than nanorobots. Because displacement grows as Ο( t)

instead of linearly in t, diffusion is fast at short distances and

relevant for coordinating activity among nearby nanorobots,

but slow over long distances. Chemicals can signal medically

relevant events [24], and also be used for nanorobots

communication. Communication ideally involves chemicals

not otherwise found in the body (to produce low signal noise

level) which are biologically inert over the relevant time scale

of the nanorobot task, and can later be cleared from the body

by existing biological processes [3].

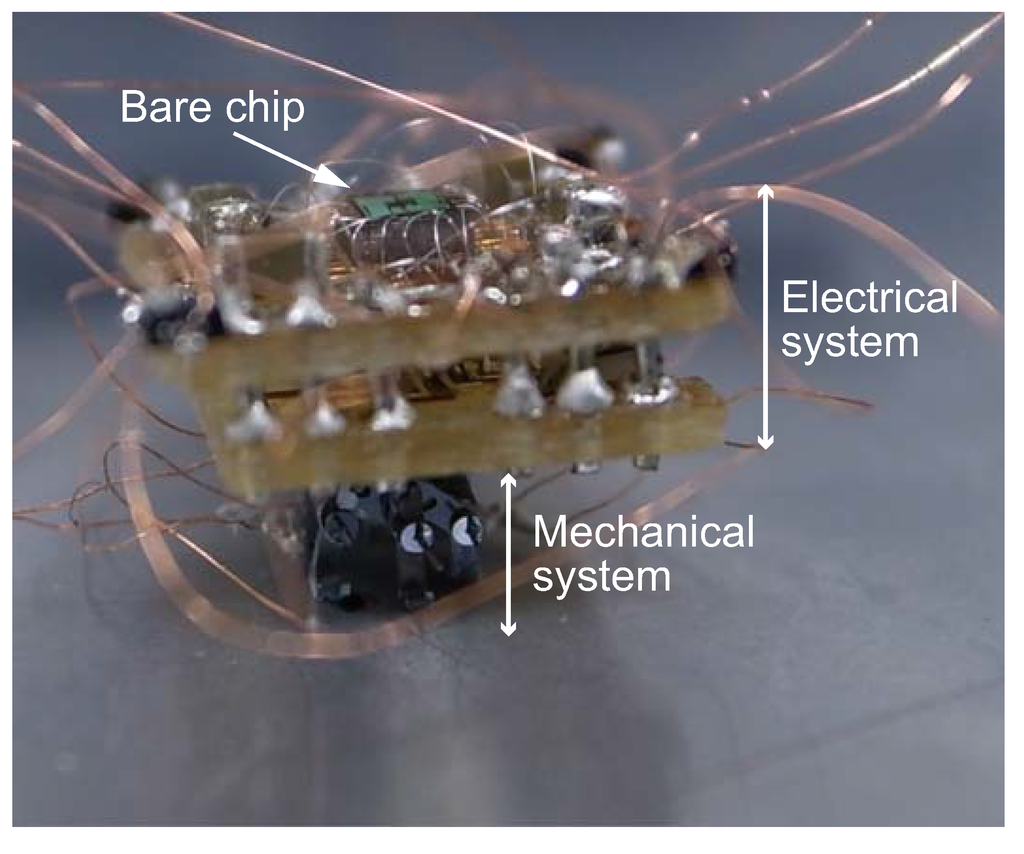

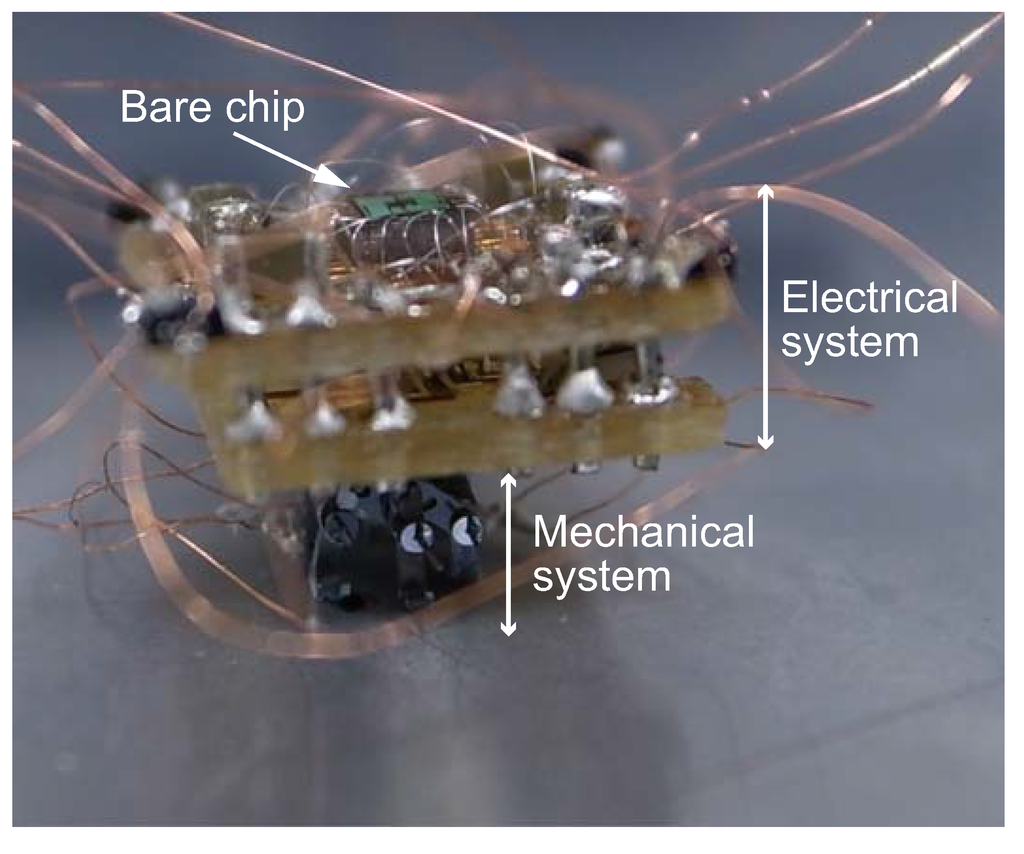

III. NANOROBOT DESIGN

Virtual Reality was considered a suitable approach for

nanorobot design and for the use of macro- and micro-robotics

concepts given certain theoretical and practical aspects that

focus on its domain of application. The nanodevice design

must be robust enough to operate in an aqueous environment

with movement having six-degrees of freedom. The nanorobot

design is derived from biological models and is comprised of

components such as molecular sorting rotors and a robot arm

(telescoping manipulator) [25]. The nanorobot exteriors

considered is comprised of diamondoid new material [26],

[27] to which may be attached an artificial glycocalyx surface

that minimizes fibrinogen (and other blood protein) absorption

and bioactivity, thus ensuring sufficient biocompatibility for

the nanorobot to avoid immune system attack [3]. Different

molecule types are distinguished by a series of chemotactic

sensors whose binding sites have a different affinity for each

kind of molecule [3].

The control system must ensure a suitable performance. It

can be demonstrated with a determined number of nanorobots

responding as fast as possible for a specific task based

scenario. In our work, we consider nanorobots flowing in a

blood vessel with a small target area on the wall emitting a

specific chemical. Manufacturing better sensors and actuators

with nanoscale sizes is advancing [28], [9]. The nanorobots,

designed with sensors for this chemical, must find the source

in a vessel wall. In the 3D workspace the target has surface

chemicals allowing the nanorobots to detect and recognize it.

IV. PHYSICAL PARAMETERS

The microenvironments of the circulatory system vary

considerably in size, flow rates, and other physical properties.

Moreover, chemicals in the blood have a range of diffusion

coefficients, and there is a range of plausible designs for the

nanorobots.

We use typical values for these properties, but our control

techniques can be modified for other values such as adjusting

detection thresholds. Small vessels have d iameters of up to

several tens of microns, and lengths of about a millimeter. The

workspace used in the simulator comprised an environment

consisting of a segment of the vessel of length L with a small

target region on the wall emitting a chemical into the fluid

(Fig. 1). Cells and nanorobots continually enter one end of the

workspace along with the fluid flow. We treat any nanorobots

not responding while within the workspace as if they did not

detect any signal, so they flow with the fluid as it leaves the

workspace.

iameters of up to

several tens of microns, and lengths of about a millimeter. The

workspace used in the simulator comprised an environment

consisting of a segment of the vessel of length L with a small

target region on the wall emitting a chemical into the fluid

(Fig. 1). Cells and nanorobots continually enter one end of the

workspace along with the fluid flow. We treat any nanorobots

not responding while within the workspace as if they did not

detect any signal, so they flow with the fluid as it leaves the

workspace.

iameters of up to

several tens of microns, and lengths of about a millimeter. The

workspace used in the simulator comprised an environment

consisting of a segment of the vessel of length L with a small

target region on the wall emitting a chemical into the fluid

(Fig. 1). Cells and nanorobots continually enter one end of the

workspace along with the fluid flow. We treat any nanorobots

not responding while within the workspace as if they did not

detect any signal, so they flow with the fluid as it leaves the

workspace.

iameters of up to

several tens of microns, and lengths of about a millimeter. The

workspace used in the simulator comprised an environment

consisting of a segment of the vessel of length L with a small

target region on the wall emitting a chemical into the fluid

(Fig. 1). Cells and nanorobots continually enter one end of the

workspace along with the fluid flow. We treat any nanorobots

not responding while within the workspace as if they did not

detect any signal, so they flow with the fluid as it leaves the

workspace.

Thus, we choose the workspace length sufficient

PARAMETERS

Chemical signal

production rate Q 10 molecule/s 4 =

⋅

diffusion coefficient D 100 m /s 2 = µ

background concentration 3 3 6 10 molecule/(µm) − ×

Parameter Nominal value

average fluid velocity v =1000µm/s

vessel diameter d = 20µm

workspace length L = 50µm

density of cells 3 3 2.5 10 cell /(µm) − ×

density of nanorobots 4 3 2 10 robot/(µm) − ×

to include the region where the chemical from the target is

significantly above the background level. The cells occupy

about 1/5-th of the workspace volume, a typical hematocrit

value for small blood vessels.

Table I lists the details included in the simulator for

rendering in real time the 3D environment, including

nanorobots and chemical signal parameters. We treat the

nanorobots as cylinders, 1µm in length and 0.5µm in

diameter. Most of the cells are red blood cells, with diameter

6µm . The number densities of platelets and white blood cells

are about 1/20-th and 1/1000-th that of the red cells,

respectively. The nanorobot density equals 12 10 nanorobots in

the entire 5-liter blood volume of a typical adult. Thus a

similar number of nanorobots may be used in medical

applications [3]. The total mass of all the nanorobots is about

0.2g. Due to fluid drag and the characteristics of locomotion in

viscous fluids, nanorobots moving through the fluid at

≈1mm/s dissipate a picowatt [29]. Thus, if all the

nanorobots moved simultaneously they would use about one

watt, compared to a typical person’s 100-watt resting power

consumption.

As a specific example, we consider a typical protein

produced in response to injury, with concentration near the

injured tissue of ≈ 30ng / ml and background concentration in

the bloodstream about 300 times smaller. A typical molecular

weight of 4 10 Dalton leads to the parameter values for the

chemical signal in Table I. This choice provides an interesting

nanorobot task, though we could equally well study tasks

involving chemicals with different concentrations relevant for

other biomedical engineering applications [21]. In our study,

the chemical signal was taken to be produced uniformly over

the target region at the rate Q. The background concentration,

listed in Table I, is a significant sensory parameter, because

the signal rapidly dilutes as it diffuses from the source.

V. NANOROBOT BEHAVIORS CONTROL

In our research, with aims of addressing analyses and

validation for feasible nanorobot control design automation,

the Nanorobot Control Design (NCD) simulator was

developed, which is software for nanorobots in environments

with fluids dominated by Brownian motion and viscous rather

than inertial forces. We examine several practical control

techniques for nanorobot motions. First, as a point of

comparison, we use the nanorobots’ small Brownian motions

to find the target by random search. In a second method, the

nanorobots monitor for chemical concentration significantly

above the background level. After detecting the signal, a

nanorobot estimates the concentration gradient and moves

toward higher concentrations until it reaches the target. In the

third approach, nanorobots at the target release another

chemical which others use as an additional guiding signal to

the target. With our signal concentrations, only nanorobots

passing within a few microns of the target are likely to detect

the signal. Thus, we improve the response by having the

nanorobots maintain positions near the vessel wall instead of

floating throughout the volume flow in the vessel (Fig. 1). In

the render modeling was used a vein wall with grid texture to

enable better depth and distance perception in the 3D

workspace. A key choice in chemical signaling is the

measurement time and detection threshold at which the signal

is considered to be received. Due to background concentration,

some detection occurs even without the target signal. As a

guide for the choice of threshold, we use the diffusive capture

rate α for a sphere of radius R in a region with concentration

as:

α = 4πDRC (5)

where the concentration for other shapes such as cylinders are

about the same [29]. With independent random motions for the

molecules, detection over a time interval ∆t is a Poisson

process with mean value α∆t .

Using Table I,

α ≈ 0.5molecule / s at the background concentration and

≈ 150 near the source.

With the target on the vessel wall, fluid

velocity near the target is lower than the average velocity v in

Table I.

When objects occupy only a small fraction of the

volume the velocity at distance r from the center of the vessel

is:

2 (1 ( /( / 2)) )

2 w = v − r d , (6)

and with the cells, the velocity shows somewhat a parabolic

flow [3], but similar enough for this parabolic profile to give a

useful design guideline.

The control design has to avoid nanorobots to miss the target

as well as to spend power in unnecessary active locomotion.

Obviously, after detecting the signal, for the nanorobot to

move far against the bloodstream, and go around numerous

blood cells, to reach the target may waste precious time and

energy. Thus, a reasonable design choice is for nanorobots to

respond within at most 10µm downstream of the target.

View of simulator workspace showing the vessel wall, cells and

nanorobots. The nanorobot is considerably smaller than the 6µm cell

diameter.

Figure 2: Nominal behavior of a nanorobot passing above the target

(small gray circle) with the fluid moving to the right. Thick dashed line

shows initial passive motion, lasting about 10ms, as the nanorobot

determines signal concentration is significantly above background.

Distances are in microns.

nanorobot 2µm from the wall encounters fluid velocity

≈ 400µm/s .

Therefore, it takes about 30ms to move 10µm,

during which time it will detect, on average, ≈ 3 signal

molecules while the background concentration has ≈ 1%

probability to give even a single detection in this time. Thus,

to save power with sensor processing, the activation threshold

to detect signals is setup for intervals of 30ms. In the

measurement to estimate the concentration gradient, the

sensors are positioned on the surface of nanorobot’s

extremities. After detecting the signal, the nanorobot estimates

the direction to the target from the concentration gradient. The

process consists of alternate short movements with random

changes in direction, at a rate depending on how the

concentration changes during the move. If no signal was

detected, the nanorobot just keeps flowing with the

bloodstream saving power consumption.

In analogy with quorum sensing in bacteria, from monitoring

the concentration of a signal from others, a nanorobot can

estimate the number of nanorobots at the target. So, the

nanorobot uses this information to determine when enough

nanorobots are at the target, thereby terminating any additional

“attractant” signal a nanorobot may be releasing. In our

investigation, the nanorobots stop attracting others once

enough nanorobots have responded. The amount is considered

enough when the target region is densely covered by

nanorobots. Thus, for investigation purposes, values of N={10,

20} were set up in the simulator as a reasonable amount of

nanorobots to the plaque target lesion. A feasible continuation

of this procedure would be to have the nanorobots emit a

different signal that others, not already at the target, interpret

as an indication they no longer need to respond, thereby

leaving them free to continue monitoring for other target areas.

Detecting multiple signaling chemicals requires sensors for

more than one chemical.

The following control methods were considered:

• Random: nanorobots moving passively with the fluid

reaching the target only if they bump into it due to

Brownian motion.

• Follow gradient: nanorobots monitor concentration

intensity for E-cadherin signals, when detected, measure

and follow the gradient until reaching the target. If the

gradient estimate subsequent to signal detection finds no

additional signal in 50ms, the nanorobot considers the

signal to be a false positive and continues flowing with

the fluid.

• Follow gradient with attractant: as above, but nanorobots

arriving at the target, they release in addition a different

chemical signal used by others to improve their ability to

find the target.

The third technique involving communication among the

nanorobots is quite suitable to improve the nanorobots’

behavior performance. By comparing these techniques, we can

evaluate the benefit of chemical communication among

nanorobots to work on typical biomedical applications.

VI. SIMULATOR RESULTS

Q , which is the chemical signal as molecules per second.

The diffusion coefficient is represented by D, and

the diffusion

equation is:

D∇ C = v∂C / ∂x 2 , (7)

TABLE II Detailed simulation depicting 90 experiments with the

amount of 1/3 for each control method. Respective colors represent

the cases for nanorobot behavior based on (a) dark for gradient with

attractant, (b) blue for follow gradient, or (c) green for random

motion.

origin and no net flux across the boundary plane at y = 0,

determines the steady-state concentration C,

which is

molecules per 3 µm or chemical concentration at point (x, y, z):

( )/(2 )

2 ( , , ) v r x D e

Dr

Q C x y z − −

⋅

= π

(8)

where

2 2 2 r = x + y + z (9)

is the distance to the chemical signal source [29].

Fig. 2 is an illustration of nanorobot behavior. The fluid flow

pushes the concentration of the diffusing signal downstream.

Consequently a nanorobot passing more than a few microns

from the source won’t detect the signal while it is still

relatively near the source. As an example, considering the

parameters from Table I, when nanorobots passing close

enough, they detect on average the higher signal concentration

within about 10ms.

Thus, keeping their motion near the vessel

wall, the signal detection happens after these have moved at

most 10µm past the source. Therefore, it provides about

5nanorobot/s arriving at the tumor cell in the small venule.

Eq. (8) also illustrates a design trade-off for chemical signals

the nanorobots could release. Instead of the diffusion

coefficient associated with the chemical from the target, such

additional signals would use other molecules which could, by

design, have a different diffusion coefficient.

From Eq. (8), the

effect of the fluid motion becomes significant at distances

beyond O(D/ v). Thus, notwithstanding the fluid flow, larger

diffusion constants allow further spread upstream.

On the

other hand, the O(1/ D) overall factor in Eq. (8) means lower

concentrations. Furthermore, the concentration of the new

signal is time dependent since the source strength increases as

more nanorobots reach the target and the signal from each

nanorobot requires time ( / ) 2 O r D to reach a distance r.

Therefore, faster diffusion results in lower concentrations,

requiring more time for other nanorobots to determine

gradients. Hence, chemical diffusion could be more efficient

for nanorobot communication, if the signals are increasing in

a steady, constant and progressively manner.

Nanorobots passing within ≈ 0.1µm of the target usually

bump into it. Those passing within a few microns often detect

the signal, which spreads a bit further upstream and away from

the single tumor due to the slow fluid motion near the venule’s

wall and the cells motion. Nanorobots close to the wall also

benefit from the slower fluid motion by having more time to

detect the signal, as discussed previously. Thus, the present 3D

simulation provides guidelines for nanorobot communication

and activation control, as well as for sensor manufacturing

design. We use an “attractant” signal with the same value of D

as the original signal. Each nanorobot can release at one-tenth

the rate of the target over the times considered here.

Distinct performances were observed throughout a set of

analyses obtained from the NCD software, where the

nanorobots use also chemical sensors as the communication

technique to interact dynamically with the 3D environment,

and to achieve a more successful collective coordination. Fig.

3 shows the virtual environment in our study, comprised a

small venule vessel which contains nanorobots, the red blood

cells (RBCs) and a single tumor cell, which is the target area

on the vessel wall. Here, the target area is overleaped by the

RBCs.

In the simulation, the nanorobots search for possible

small cancer tumor into the workspace crowded by RBCs.

In Fig. 4 it could be observed in a detailed fashion the

information about the nanorobots behaviors.

Table II provides

a summary and comparison of the control techniques

evaluated using the NCD simulator. It shows the time required

for 10 and 20 robots to identify and reach the target. Each

value is the mean of 30 repetitions of the simulation, with

standard deviation in parentheses. The error estimate for these

mean values is 30 times smaller than the standard deviations

listed here. For comparison, if every nanorobot passing

through the vessel found the target, 20 nanorobots would

arrive at the target in about 0.2s. As one would expect,

enabling nanorobots to detect and follow gradient

concentration increases the probability for nanorobots to find

the target, where in comparison with random motion the

nanorobots show a better performance of 23%. Further, for

gradient with “attractant”, we see that using the signals allows

the nanorobots to find and reach the target in the 3D

workspace 46% faster than that with random motions. This is

a remarkable improvement in performance for response time.

IEEE ICARCV 2006 International Conference on Control, Automation, Robotics and Vision

VII.

CONCLUSION AND REMARKS

The development of nanorobots may provide remarkable

advances for diagnosis and treatment of cancer. Using

chemical sensors they can be programmed to detect different

levels of E-cadherin and beta-catenin in primary and

metastatic phases. Our work has shown a comprehensive

methodology on tracking single tumor cell in a small venule,

where nanorobots using communication techniques to increase

their collective efficiency. The simulation has clearly

demonstrated how better time responses can be achieved for

tumor detection, if chemical signals are incorporated as part of

nanorobot control strategy. As observed in the study, the

follow gradient with attractant signal is a practical method for

orientation and coordination of nanorobots. It has enabled a

better performance for nanorobots to detect and reach

cancerous targets. This approach can be useful in the treatment

of many patients for a detailed examination and intervention.

A single tumor cell can be characterized as a typical

endothelial cell mutation with profound consequences for

patients suffering from cancer. Endothelial cells have a large

number of functions and may play an important role in human

health. They also serve as part of the structure forming the

inside blood vessels, which are spread throughout every single

organ or system comprising our body. An abnormal cell

mutation and reproduction can represent a wide variety of

malignant cases in the oncology field. Thus, a better

understanding and the development of new tools based on

nanotechnology through chemical sensors may represent

important advances to identify, and combat the initial stage of

tumor development. Nanorobots can help with significant

improvement on cell therapy techniques, and unprecedented

positive results to save lives.

No comments:

Post a Comment